Iran Coated Sand (ICS)

The first and only successful exporter of shell sand in Iran

Iran Coated Sand Production Company (ICS) was established in 1994 with the most up-to-date German production line, with the exclusive method of mixing sand and resin in order to improve the quality of foundry products. Regardless of the daily mass production, in order to reduce the time of sending customers’ requests, the good flexibility of the above production method has made it possible to accept different requests for the quality of sand required by the consumer. Besides meeting the needs of market consumption, we are proud to be the first and only successful exporter of shell sand in Iran to other countries. The high quality and production capacity of the company has satisfied and continued the requests of our market and foreign customers and has encouraged the continuation of our activities.

Ics Image Gallery

Ics Product Range

Iran Coated Sand is committed to intensive research, using the latest technical methods on the expertise of the chemistry specialists. This enables us to offer foundries a comprehensive product range for all requiremernts applications.

| NO | ICS Code | Hot Tensile Strength (Kg/cm2) Tol. ± 0.75 | A.F.S. Tol. ± 5 | L.O.I. (V). (cm3/gr) Tol. ± 0.5 |

|---|---|---|---|---|

| 1 | 024-K | 8 | 35 | 10 |

| 2 | 024 | 9.5-10.5 | 35 | 10 |

| 3 | 524-L | 11-12 | 35 | 11 |

| 4 | 524 | 12.5-13.5 | 35 | 11 |

| 5 | 524-D | 13.5-14.5 | 35 | 12 |

| 6 | 524-T | 14.5-15.5 | 35 | 12 |

| 7 | 524-M | 20-21 | 35 | 15 |

| 8 | 524-H | 25-26 | 35 | 27 |

| 9 | 525-L | 9.5-10.5 | 50 | 10 |

| 10 | 525-B | 10.5-11.5 | 50 | 10 |

| 11 | 525-H | 15-16 | 50 | 11 |

| 12 | 525-T | 14-15 | 50 | 11 |

| 13 | 526-J | 8 | 60 | 10 |

| 14 | 526-B | 11.5-12.5 | 60 | 10 |

| 15 | 526-A | 12.5-13.5 | 60 | 11 |

| 16 | 526-L | 14.5 -15.5 | 60 | 12 |

| 17 | 527-L | 8-9 | 70 | 10 |

| 18 | 527-AL | 9 -10 | 70 | 10 |

| 19 | 527-B | 12.5-13.5 | 70 | 12 |

| 20 | 527 | 14.5-15.5 | 70 | 12 |

| 21 | 527-M | 15.5-16.5 | 70 | 12 |

| 22 | 037 | 17-18 | 70 | 15 |

| 23 | 529-F | 10-11 | 80 | 12 |

| 24 | 529* | 11-12 | 80 | 11 |

| 25 | 529-S | 13.5-14.5 | 80 | 12 |

| 26 | 529 | 14.5-15.5 | 80 | 12 |

| 27 | 529-A | 15.5-16.5 | 80 | 13 |

| 28 | 039 | 17-18 | 80 | 15 |

| 29 | 539-5 | 18-19 | 80 | 15 |

| 30 | 529-H | 25-26 | 80 | 24 |

| 31 | 1379 | 20-21 | 80 | 17 |

| 32 | 1379-A | 27.5-28.5 | 80 | 27 |

There is a great flexibility to accept customer desired properties along with Economic considerations.

Customer Support , After Sales Service

Resin Coated Sand

SHELL MOLDING and COREMACKING is a process in which a mold or core is formed from a mixture of sand and a thermosetting resin binder that is placed against a heated metal pattern. When the mixture is heated in this process, the resin cures, causing the sand grains to adhere to each other, forming a sturdy shell /core.

In the scope of after-sales service, our expert team in R & D section are proactive and active with customer in checking, troubleshooting and solving their production problems.

Also, ICS is with customer to provide advice and semi plan to create new shell mold and core making lines or expansion and optimization of the existing production method.

Latest News

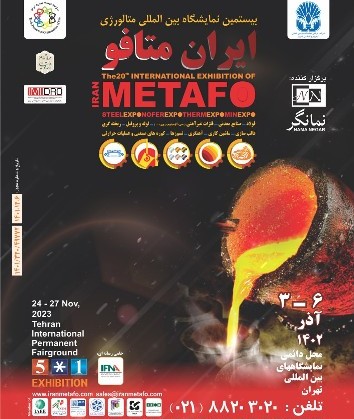

20th International Metallurgical Fair 2023

Iran Coated Sand will Participate on Fair During 24-27 / Nov / 2023

19th Metafo Exhibition 2022 Tehran ICS stand

Exhibition & Events ICS co. Past trade fairs: 19th Metafo Exhibition 2022 Tehran ICS stand A meeting place for Iran and foreign foundries, For 2